With Autodesk Gallery you can view and present 3D model and file easily online. V-Block SolidWorks 3D Model Exercise 9.

Design And Fabrication Of V Block Fixtures For Metal Holding Operations

L2 number of wpcdmaxpressure pad heightclearance for loading and unloading.

. Fixture is made of cast. The official platform from Autodesk for designers and engineers to share and download 3D models rendering pictures CAD files CAD model and other related materials. Thanks for Contacting Us.

A simple v block datum structure may not provide the accuracy you need. All the lines are created using the Line sketch tool. I realize one way to do it would be with an endmill that had a.

Industrial CNC VMC. V block design for holding round stock. Order Your Industrial Tools At Grizzly.

It is used to different types of diameters and also used differend height of job Eg60mm to 400mm used in single V Block setup. Five items to consider when designing your V-block. Follow the dimensions given the below isometric view of v block part.

It is very simple to create this 3D V-block design and also learn Mirror feature tool. I realize one way to do it would be with an endmill that had a point ground to an included angle of 90 degrees. It is also possible to locate the shaft in a V-block in place of a box with circular hole.

V-Blocks used in Jig and Weld Fixtures are designed with some thought using Pro-E Wildfire 40. Do high-quality work on custom-fabricated frames exhaust pipes roll cages and other parts that require steel tubing with this Eastwood Drill Press V-Block Fixture. In the design of angle- plate tool body the vertical member should be either made of same size or smaller than the horizontal member in order to maintain the required rigidity of the tool and to ensure accuracy in the part.

These blocks are a great accessory for your drill press. SolidWorks Sketch Tools Used -Line Sketch Tool. Free 2-Day Shipping wAmazon Prime.

We Are The Purveyors Of Fine Machinery. DDesign of fixture body. V- Block Datum Fixtures.

DMT has you covered with our centering vice experience. The overhang of turning fixtures should be minimum bare necessary for the operation. In our last Jig or Weld Fixture Design blog we talked about different ways to locate a round rod or tube.

Give us a call we can help. Vertical horizontal multiple part numbers no problem. Rs 500 Unit Get Latest Price.

Two basic locating principles are 3-2-1 locating and 4-2-1 locating. The Center-It makes it easy to drill through the center of bar stock and round tubing. This lesson is part of the weld fixture design blog at Renta.

V BLOCK DESIGN IN SOLIDWORKS. It needs to be exactly the same distance from edge of the block to center of the V on both sides to allow quick centering of the work. Jig and Fixture Design General Information All six degrees of freedom along X Y and Z axis both laterally and rotationally need be constrained for a part to be fully located.

Hence the v-block of an angle 90 degrees is used to support the tubes. Discover the Right Industrial Components for the Task at Hand. Use this block to hold workpieces at precise angles.

The Art and Science of. V block fixture. One of the more common ways is with a v-block.

This V Blocks are semi automatic Equally adjust deponding on various diameter jobs. Fixture should be balanced with workpiece in position. It provides equilibrium but not.

Height of supporting block should be equal to height of V block. Figure 3 V-block 26 Hole Sizes Locating Pin Sizes. Use them with the Eastwood Vise Press Brake to create flexible.

Also used center line for getting positions of. L1height of V blockc tdiameter of wpdmax Thickness of supporting blockts15t L2L12tsL2. Posted by rentapenblog on Jan 3 2012 in Drawings ProENGINEER Tolerancing Weld Fixture Design 101 Comments Off on Three Ways to Detail a V-Block Jig or Weld Fixture Design 101.

Ad Read Customer Reviews Find Best Sellers. Machine axis by sliding v-block which can be operated with knurled screw. Adjust the block to the desired angle tighten the set screw on the bottom of the block to lock it in place and clamp the workpiece to the block clamps sold separately.

Ad Buy Grizzly Today. Today we will discuss some of the questions that help you decide the material modeling method using ProE 40 and fastener locations. Do you have a round part that may not be consistently round or maintain its diameter.

Shop Our Product Offerings. Adjustable Equlizer V Blocks-. Three Ways to Detail a V-Block Jig or Weld Fixture Design 101.

Design of base plate. The clamping arrangement should be capable of withstanding the various forces developed during operation. Since the v-block is a separate component which can be placed on the fixture so as to support the tubes has its bottom surface lined with a silicone layer of 05mm thickness for stability.

V block design for holding round stock. Ad MSC Industrial Supply Co serving the metalworking safety and MRO fields for 75 years. It needs to be exactly the same distance from edge of the block to center of the V on both sides to allow quick centering of the work.

The first 3-2-1 locating is the minimum requirement for location.

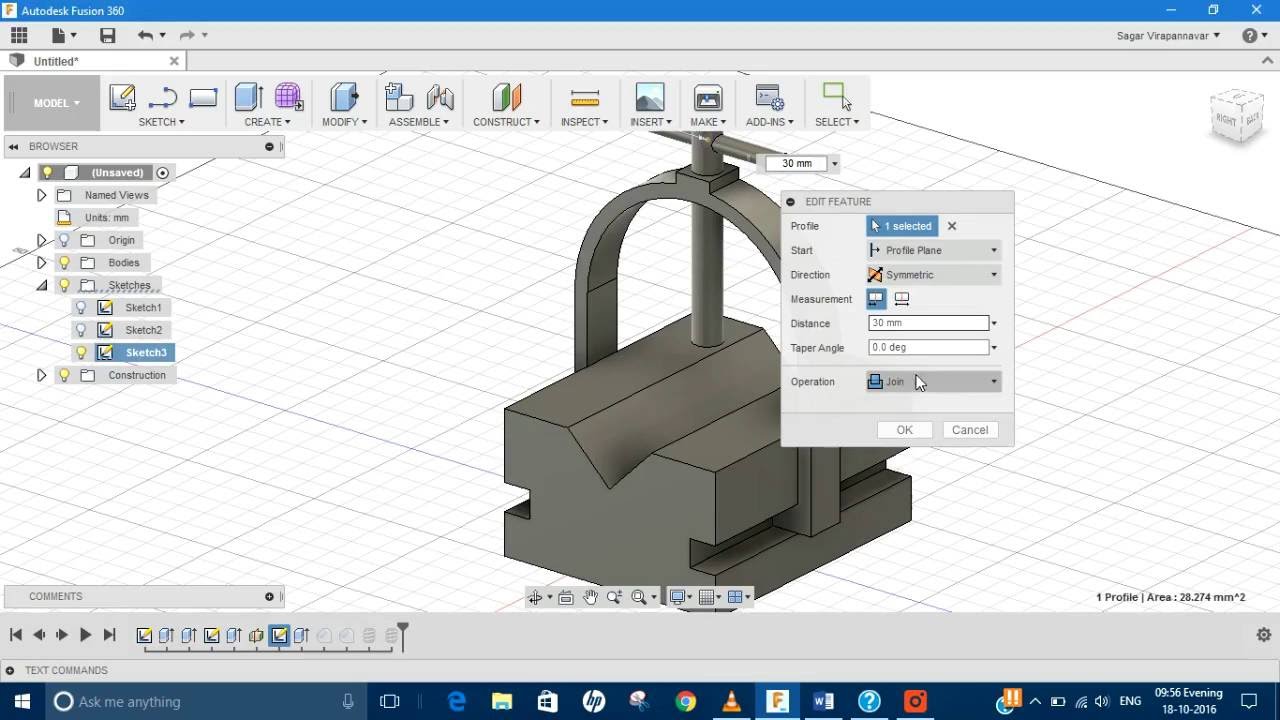

Jigs And Fixtures V Block Design Autodesk Online Gallery

V Block Jig Fixture For Center Drilling Of Round Work Abm Tools

Design And Fabrication Of V Block Fixtures For Metal Holding Operations

V Blocks Weld Fixture Specialists

V Blocks Chain Cable Clamping Advanced Machine Engineering Co

19339 Cmm Fixturing Magnetic Vee Blocks Wixroyd

Jigs And Fixtures Using Fusion 360 Introduction V Block Assembly Design Youtube

0 comments

Post a Comment